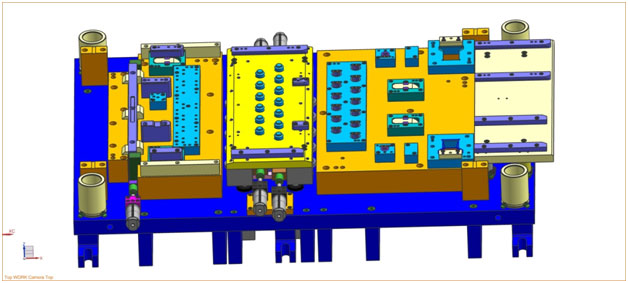

FKI USA construction of a new innovative die

FKI USA recently completed the construction of a new innovative die which produces a range of parts for the transportation market.

The design uses gags that can turn on or turn off certain features between press strokes. This allows the customer to produce a range of parts using 3 strip widths and 9 different lengths of parts. There are 21 high speed cylinders on the die that allow different features to be added to the part minimizing the need for secondary operations. The servo feeder receives input from the computer that varies the progression on different press strokes.